GCC, a conveyor closure for (almost) all cases

It has been over 40 years since company founder Dr.-Ing. Jochen Stöbich developed the first conveyor closure (FAA). Today, STÖBICH is a leader in preventive structural fire protection and develops product innovations such as the Global Conveyor Closure (GCC).

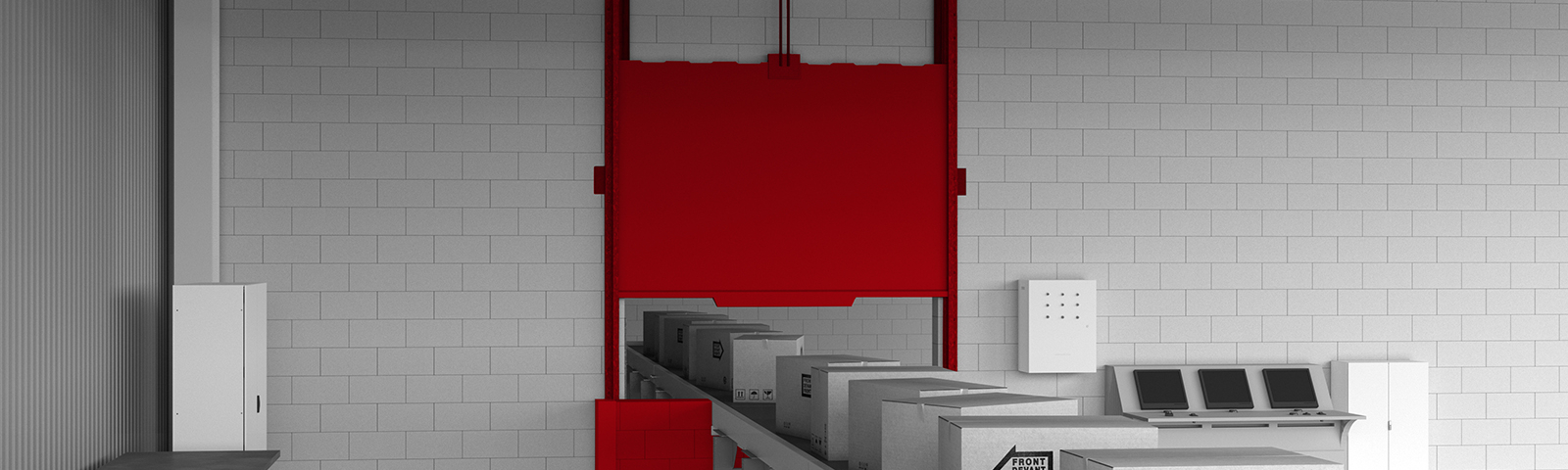

It can be found, among other places, in the logistics centre of the brand-name shoe manufacturer adidas in Rieste, where it provides fire protection for the conveyor system: We are talking about the GCC, the Global Conveyor Closure.

Conveyor Closure

(literally means "closure of the conveyor belt". In case of fire, the alarm is triggered and the GCC automatically closes the corresponding opening in the conveyor. In this way, it prevents the flames and fire gases from spreading to other sections of the production hall, as happened in the major fire at Bahlsen in 1978. This inferno is considered the big bang of the STÖBICH empire because it inspired Dr.-Ing. Jochen Stöbich to develop the first conveyor closure.

The

"Global"

in the product name refers to the applicability of the conveyor system closure: the GCC is a European tested product according to EN 1366-7 up to a required protection classification of EI 90 and thus a global or European player among the FAAs.

What is special about the GCC?

The GCC is a so-called fire protection closure in the course of track-bound conveyor systems for a) separated and b) continuous conveyor technology. a) means that the conveyor technology is separated in the closing area of the FAA (necessary gap dimension approx. 80 mm). In the case of b), the conveyor system is guided through the FAA without separation. In this case, the FAA consists of a slider blade above the conveyor system as a movable part and a conveyor system bulkhead (fixed panel for short) below the conveyor level.

What advantages does the GCC offer?

- Is assembled on site from ready-made elements (slider, guides, crimping, drive unit)

- can therefore be easily transported

- adapts accordingly to the respective installation situation and conveyor technology variant

- available in vertical and horizontal closing direction

The slim, space-saving system requires only a small overlap on the wall around the opening. The outstanding feature of the GCC is the very thin slide blade thickness. Even small conveying media for totes or cartons can thus be designed as separate conveying systems, as only one very small separation point is required. In this case, several conveying sections through one wall opening can be realised without any problems. This makes the GCC so ideal for interrupted conveyor technology, but also for roller, belt and chain conveyors.

➥ Technical data and further info on the GCC provide a good insight into the product. If you have any specific questions, you can also contact us directly at

➥ contact us.